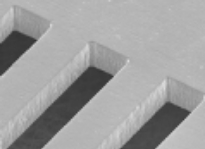

HGPTMMetal Mask

HGP is the metal mask developed for cream solder that shows low shearing stress on relatively coarse aperture walls. It achieves continuous printing without blurring for the sharper shape of aperture edges than that of SHG.

![]()

Main Features

- It provides excellent solder removal performance for cream solder that shows low shearing stress on relatively coarse aperture walls.

- Its sharp aperture edges are effective in improvement for solder filling on the squeegee surface and prevention for solder seeping from the apertures on the printing surface.

Performance

-

-

HG

(conventional products)

-

-

HGP

-

-

SHG

| Product type | Aperture open (printing surface) | |

|---|---|---|

| Wall roughness Ra max. | Aperture edge, acute angle | |

| HG (conventional products) |

0.8μm | ≦7μm |

| HGP | 0.8μm | ≦2μm |

| SHG | 0.4μm | ≦3μm |

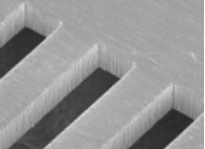

SHGTMstencil

This stencil can achieve the stable printing during the continuous printing against very small components and high aspect ratio..

![]()

Features

- SHG has smoother opening side wall and sharpened corner-edge as compared to conventional

Stencil so that meet stable printing for high aspect ratio with very small components. - By adding PRO-coating on SHG on both opening side wall and pcb side of stencil, it could be given assisted reduction of the range of printed volume deviation in any range of aspect ratio.

・This stencil can reduce an unstable solder volume and height.

・This stencil can solve solder paste bleeding during the continuous printing.

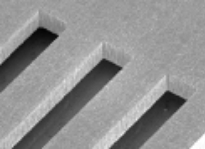

HG stencil

HG stencil is more suitable for printing of SMT than standard laser cut stencil. It has smoother roughness of aperture wall than the standard laser cut stencil has. This stencil provides good-quality printing.

![]()

Main Features

- Shorter delivery times !

- It is possible to correspond to fine pitch components as QFP

Aperture shape and wall shape of HG stencil

| Ave. | Max. | 3σ | |

|---|---|---|---|

| Ra | 0.4 | 0.8 | 0.2 |

| Rz | 5.5 | 7.9 | 4.4 |

| Rzjis | 2.9 | 4.4 | 2.5 |

Above is for reference

unit:μm

Detail

| Processing method | Laser cut and special treatment |

|---|---|

| Range of adaptation | 0402㎜, 0.3~0.5㎜ PitchCSP, 0.3~0.4㎜ PitchQFP |

| Tolerance of aperture size | +-10μm |

| Tolerance of thickness | +-8μm |

| L/T | From 1 day to 3 days |

Above is for reference

Laser stencil

Standard stencil is possible to correspond to 0.3mm~0.5mmpitch components and small components such as 0603mm components for high density printing. It also meet shorter delivery time.

![]()

Main Features

- Provide a short delivery time!

-

Fine pitch , small size

It is possible to print small size components.

Aperture shape and wall shape of standard Laser cut stencil

| Ave. | Max. | 3σ | |

|---|---|---|---|

| Ra | 1.1 | 1.5 | 0.7 |

| Rz | 6.8 | 8.0 | 2.4 |

| Rzjis | 5.6 | 6.8 | 2.3 |

Above is for reference

unit:μm

Detail

| Processing method | Laser cut |

|---|---|

| Range of adaptation | 0.6mmPitchCSP,0.5mmPitchQFP |

| Tolerance of aperture size | +-10μm |

| Tolerance of thickness | +-8μm |

| L/T | From 1 day to 3 days |

Above is for reference